Secure U.S. Manufacturing

U.S. manufacturing with integrity. On time and on budget.

REDCOM Laboratories, Inc. is a U.S. manufacturer based in Victor, New York, USA. We have more than 45 years of experience manufacturing products for a diverse set of market verticals including telecommunications, defense, aerospace, industrial, energy, and transportation. If your product contains circuit boards and electronics for use by the military, government agencies, or first responders, REDCOM’s Advanced Manufacturing can help bring your product to market quickly and securely.

Home / Secure U.S. Manufacturing

REDCOM advanced manufacturing

Outsourcing the manufacturing of your product can be risky. With hacks and data breaches making the news every day, companies need to be more conscious of security than ever before. If you need a U.S.-based manufacturer to help bring a specialty product to market in the defense industry, you need 100% confidence that your intellectual property won’t end up in the hands of a competitor or foreign country.

REDCOM has been manufacturing for highly secretive enterprise, military, and government customers for decades. Our customers trust us with their most sensitive designs and information because they know REDCOM has the controls in place to secure their projects from start to finish.

The REDCOM advantage

QMS for defense and aerospace applications. REDCOM is committed to ensuring your products are manufactured to the most rigorous quality standards in the industry. Our quality management system is certified to ISO 9001:2015 and AS9100D:2016 (aviation, space, & defense). We constantly monitor our quality objectives and control to strive for continuous improvement.

We go beyond the typical NDA to keep your IP secure. Our fully integrated secure ERP system only grants access to those individuals necessary to the manufacturing process. All subcontractors are required to maintain ISO certification and strict confidentiality.

Secure supply chain management. When you partner with REDCOM, you don’t have to be concerned about counterfeit parts and sub-par materials. We work directly with manufacturers and vetted suppliers to ensure that we source the best and most reliable components for every job. We have strategic procurement agreements in place to ensure parts are always available and in stock to meet lead time requirements. Finally, we’ve made arrangements with our trusted distributors to lock in the best prices.

Representative work

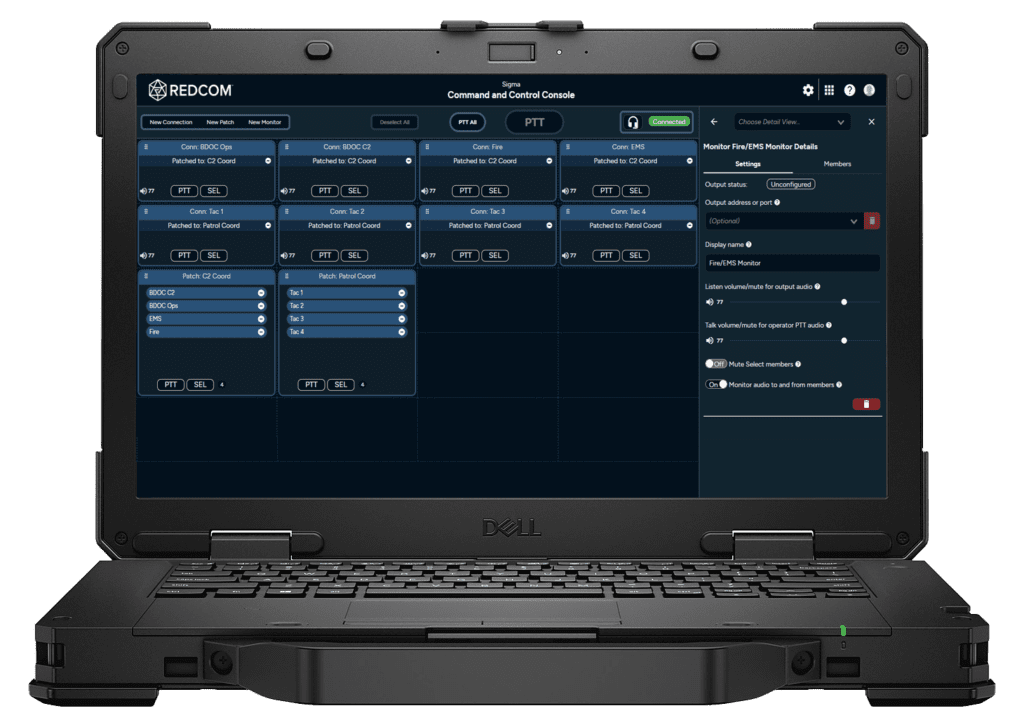

REDCOM Advanced Manufacturing serves select customers in demanding markets where reliability truly matters. Some of our work includes deployable tactical systems, field communications devices, mobile servers, military optics position control, environmental sensors, grid monitoring systems, energy management systems, and equipment to process DNA samples.

Our Core Competencies

Printed Circuit Board Assembly

- Simple-to-high complexity PCBAs

- Surface Mount & Through-Hole Technology

- Manual assembly

- Depanelization/PCB array configuration

- Automatic Optical Inspection

- Robotic repair/rework

- X-Ray

- 3D printing

- Aqueous wash

- Automated conformal coating

Our Core Competencies

System-Level Assembly

- Turnkey box build & electro- mechanical assembly

- Board-level and system-level test

- HALT & HASS environmental testing

- Warranty services

- Software installation

- Package, label, and bar code

- New product introduction

- Component selection to improve manufacturability

Our Core Competencies

Secure Manufacturing

- Focused Factory

- ITAR-registered manufacturing

- Subcontractor clearance

- Integrated Enterprise Resource Planning (ERP)

- Secure supply chain management

- Fraudulent component prevention (GIDEP)

- Component Lifecycle Analysis (SiliconExpert)